PVC/PET/OPS Shrink Sleeving Labeling Machine for PET Bottle

Capacity: 6000-36000bph

| MACHINE | Dimension(mm) | 2440*1000*2200 |

| Weight | 600kg |

| Electric Power | AC3-Phase220V/380V |

| Speed | UP to 36,000BPH |

| CONTAINER | Height | MAX 320mm |

| Diameter | φ50~φ110 |

| Materials | Glass/Metal/Plastic |

| Shapes | Round/Oval/Square/Rectangle |

| LABEL | Materials | PVC/PET/OPS/OPP |

| Thickness | 0.035~0.10mm |

| Length (MAX) | 150mm |

| Flat Width (MAX) | 175mm |

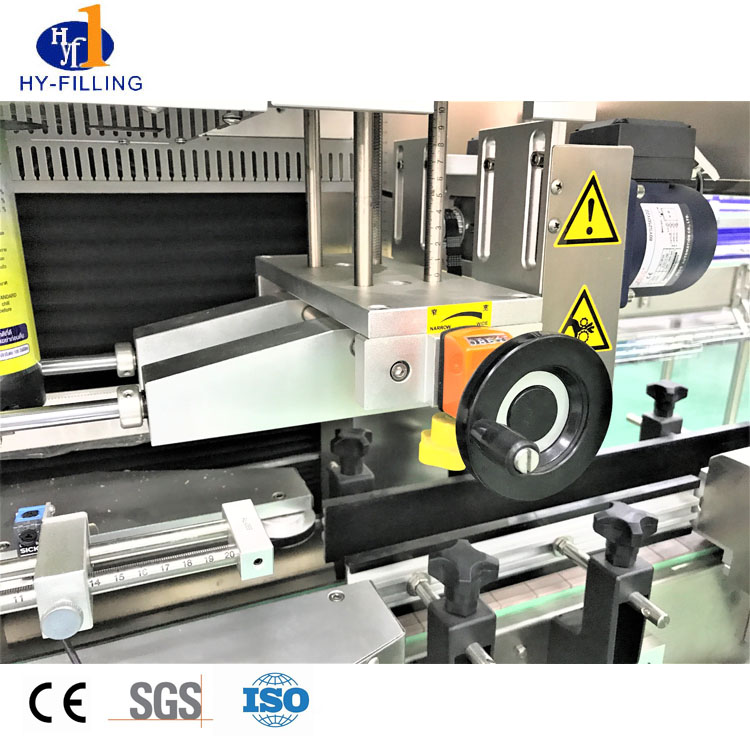

1) Advanced human-computer dialogue panel control technology is adopted, key electronic parts are all from world famous brand.

2) With quick and easy operation, the machine can be fixed to the producing line.

3) With particularly designed reamer plate in the range of specification. Reamer base do not need to be changed, only reamer needs to be changed. It is quick and convenient.

4) It applies to various types of bottle with the character of continuous motion adjustment without tools to drive the machine.

5) It is convenient and rational with the special labeling way: Pressing-style labeling.

6) The driving device of the machine makes bottle change-over very easily.

7) It applies to 5"--10" film material, and with the action of unanimity, efficiency, delivery and stop.

8) It applies to square and circular bottles after simple assembly.

9) Height can be adjusted freely with the elevating central pillar.

10) The cut length is precise with the high-agility light-twining electronic eye.

English

English